Precision

- Products

- Precision Components

- Lathe Processing

Lathe Processing

In general, even for part shapes on the assumption of milling or necessity of integration, cost reduction can be achieved by making the most of the turning process. We rise to the challenge of many materials and shapes.

Features

- Our specialty is handling the SUS family and difficult-to-machine materials.

- Materials to be machined: SUS303, SUS304, SUS304L, SUS430, SUS430F, SUS316, US316L, Kovar, Alloy 50, etc.

- Shape machining is fully completed inside NC lathes with one chuck. Secondary machining is unnecessary.

- Various platings and surface treatment are supported. (handling in collaboration with partner companies)

Introduction of main precisely processed parts

-

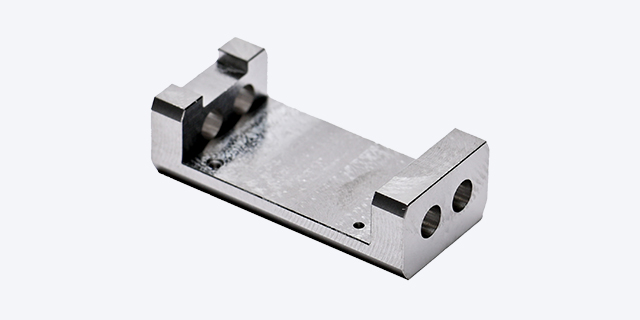

Material: SUS303

Shape: 6×7×13 mm- At first, drawings from a customer had three parts on the assumption of milling.

- We proposed integrating the three parts into one and a turning process; then we discussed the design with the customer.

- We made proposals to meet the strict cost needs of the end user, including reducing the customer's assembling processes.

-

Material: SUS303

Shape: 6×7×23 mm- At first, drawings from a customer assumed milling.

- We proposed a turning process and changed the drawings to those using a turning process.

- In the competitive quotation, we submitted the lowest price and won the order.

-

Material: SF20T

Shape: 15×15×5 mm- We achieved a finished produce with a turning process alone.

- This product was carved from a round bar.

-

Material: SF20F

Shape: di. 6×9

If you would like to request a quotation or have a detailed consultation, please use the inquiry form.

Contact usThis website uses Cookies for the purpose of improving our service, but we will not use Cookies to identify individuals. We shall obtain your agreement on the use of Cookies when you use this website. Please see our policy on protecting personal information to see how we handle personal information.

Contact us

Contact us